Road to net zero: Is carbon offsetting the best option for coffee businesses?

As coffee businesses search for new ways to be environmentally friendly, Matt Haw speaks with Sara Gibson about the pros and cons of carbon offsetting.

Environmental sustainability has become a critical focus for the coffee industry. Approximately 60% of wild coffee species are at risk of extinction, and the effects of climate change are predicted to reduce the amount of suitable coffee-growing area around the world by up to 50% by 2050.

As such, many coffee businesses are adopting initiatives to reduce their emissions – in many cases aiming to reach net zero. In fact, nearly half of all coffee launches in 2020 made at least one sustainability claim.

One term that has gained traction in the coffee industry is “carbon offsetting”, as an emerging solution for businesses aiming to reduce their carbon impact. This is where businesses pay to participate in schemes which reduce the amount of carbon dioxide in the atmosphere.

“It’s a way to make up for the carbon dioxide emissions that you create,” says Sara Gibson, co-founder of Sightseer Coffee. “This is done by purchasing carbon credits or ‘offsets’, often done via an online market.”

One of the most significant contributions to the coffee industry’s carbon footprint occurs towards the end of the supply chain. Roasting typically involves burning fossil fuels, leading to the emission of greenhouse gases. On average, 1kg of coffee produces 5kg of carbon dioxide.

Once roasted, coffee then needs to be packaged, shipped, ground, brewed, and disposed of. According to research, this final stage accounts for over one-third of the coffee industry’s total carbon footprint.

As such, many coffee shops and roasters are exploring ways to reduce their carbon emissions.

However, addressing these issues requires upfront investment in carbon-friendly strategies and equipment. For businesses already grappling with rising costs and high coffee prices, prioritising carbon reduction may be difficult.

“Achieving carbon neutrality is expensive and most coffee businesses aren’t at a place where it’s a viable option for them,” says Sara.

Furthermore, roasters and coffee shops have unavoidable energy inputs in their operations. No matter how many emission-reduction strategies they implement, they will never be carbon neutral through these means alone.

Carbon offsetting, therefore, offers a way to address the emissions that cannot be actively reduced.

Is carbon offsetting the best option?

Carbon offsetting is not without its challenges, however. One of the main frustrations lies in accurately measuring carbon emissions.

To get started, a business has to estimate its emissions. “This can be challenging in and of itself,” says Sara. “A lot of people cobble together a guesstimate using an online calculator.”

The disparity between a company’s calculated carbon emissions and what it is actually accountable for can be significant, especially for businesses with complex value chains. Coffee businesses often face challenges when determining their direct and indirect emissions. A 2021 survey revealed an error rate of up to 40% in emissions calculations among sampled businesses.

Another major concern with offsetting schemes is that they can be difficult to verify. “Recent news stories have found that ‘phantom credits’ are prevalent, and many offset projects are incomplete or ineffective.”

Carbon offsetting can therefore be viewed as a distraction from the solutions needed to address climate change.

Linked to concerns about greenwashing, critics argue that carbon offsetting fails to tackle the root causes of global warming. Instead, it gives space for “virtue signalling” – allowing companies to showcase their environmental consciousness while maintaining business as usual, without making substantial changes to their emissions.

However, for businesses with inevitable carbon emissions, it is better than doing nothing.

Part of the solution

Investing in modern, energy-efficient equipment is another good way for coffee businesses to be more carbon-friendly.

Newer electric roasters with heat recirculation systems produce significantly less carbon compared to gas-burning roasters. Additionally, installing an afterburner removes emissions and other pollutants that can harm the environment.

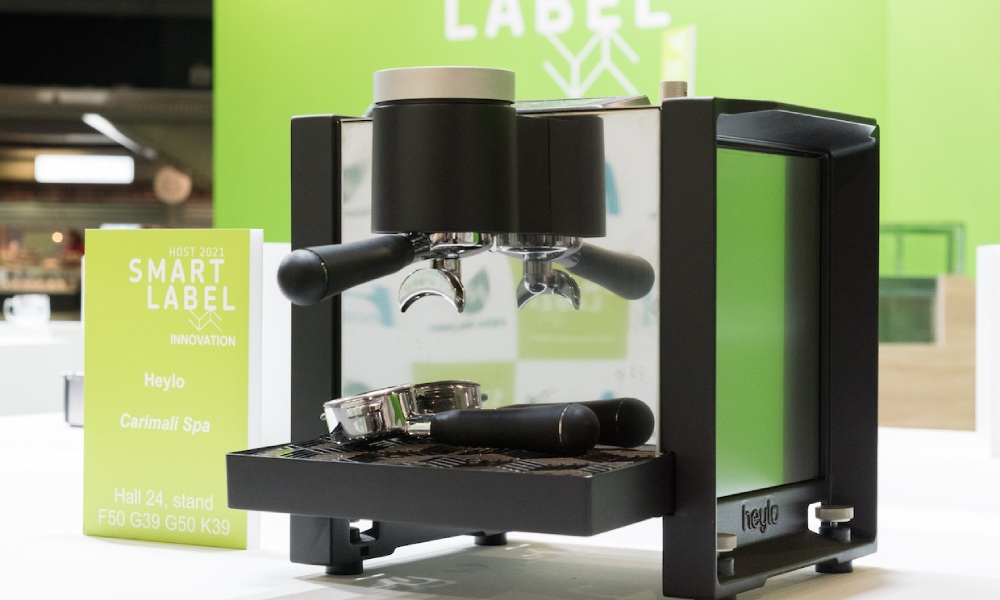

At the coffee shop stage, equipment purchasing decisions can increasingly be guided by energy-saving features. For example, Heylo’s coffee machines use an induction heating system, rather than boiling water – significantly reducing energy consumption.

Technological advancements in areas such as power electronics, electromagnetic design, and digital control have made it possible to create induction heating systems that are more than 95% efficient. Additionally, the cost of implementing these systems has significantly decreased in just the last few years.

In spite of this, achieving carbon neutrality remains a challenging goal for most businesses. For them, investing in carbon offsetting schemes may be the only viable option.

However, there is an alternative approach that could offer a more effective way forward.

Unlike offsetting, carbon insetting focuses on reducing or removing carbon emissions directly within a company’s supply chain. Insetting activities require independent verification or certification and aim to generate positive impact for communities and the environment. This regulated approach represents a more targeted strategy to address the industry’s emissions.

“Carbon insetting certainly has the potential to be more transparent and impactful,” says Sara, who sees it as something larger coffee companies should be pioneering. “They should be setting the standards for what successful insetting looks like in our industry, and creating a viable path forward that the rest of us can walk down.”

Ultimately, businesses should strive to implement carbon reduction strategies, but these alone will not fully address the carbon-positive nature of the supply chain. While carbon offsetting schemes have their challenges, they are certainly part of the solution as we transition towards a more sustainable production model.